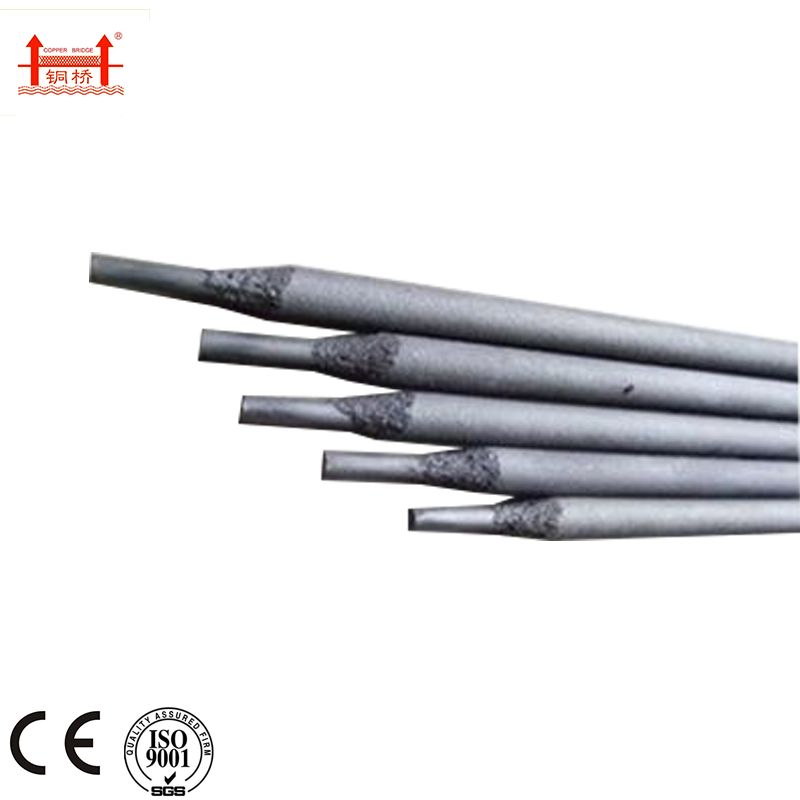

Ma Electrodes Osapanga dzimbiri CB-A102

Chidziwitso chogwiritsa ntchito ma elekitirodi osapanga dzimbiri

1. Chromium chitsulo chosapanga dzimbiri chimakhala ndi kukana kwa dzimbiri (oxidizing acid, organic acid, cavitation), kukana kutentha ndi kukana kuvala.Nthawi zambiri amagwiritsidwa ntchito m'mafakitale amagetsi, mankhwala, mafuta amafuta ndi zida zina.Chromium zosapanga dzimbiri zitsulo osauka weldability, ayenera kulabadira ndondomeko kuwotcherera, zinthu kutentha kutentha ndi kusankha ma elekitirodi yoyenera.

2. CR-13 zitsulo zosapanga dzimbiri zimakhala ndi kuuma kwakukulu pambuyo pa kuwotcherera ndipo n'zosavuta kupanga ming'alu.Ngati mtundu womwewo wa chromium zosapanga dzimbiri elekitirodi (G202, G207) ntchito kuwotcherera, ayenera preheated pamwamba 300 ° C ndi utakhazikika pafupifupi 700 ° C pambuyo kuwotcherera.Ngati kuwotcherera sangathe kuchitidwa pambuyo kuwotcherera kutentha mankhwala, ndiye kusankha chromium-nickel zosapanga dzimbiri elekitirodi (A107, A207) .

3. Chromium 17 chitsulo chosapanga dzimbiri, pofuna kupititsa patsogolo kukana kwa dzimbiri ndi kuwotcherera ndikuwonjezera kuchuluka koyenera kwa zinthu zokhazikika monga Ti, Nb, Mo, etc., weldability ndi bwino kuposa chromium 13 chitsulo chosapanga dzimbiri.Pamene mtundu womwewo wa chromium zosapanga dzimbiri elekitirodi (G302, G307) ntchito, ayenera preheated pamwamba 200 ° C ndi kutentha mozungulira 800 ° C pambuyo kuwotcherera.Ngati kuwotcherera sikungathe kutenthedwa, ndiye kusankha kwa electrode ya chromium-nickel zosapanga dzimbiri (A107, A207).CR-NI zosapanga dzimbiri ma elekitirodi ali zabwino dzimbiri kukana ndi makutidwe ndi okosijeni kukana, chimagwiritsidwa ntchito makampani mankhwala, feteleza, mafuta, mankhwala makina kupanga.

4. 0 ndi pansi angagwiritsidwe ntchito onse malo kuwotcherera.

5. 0 ndi pamwambapa kuwotcherera lathyathyathya ndi kuwotcherera fillet.

6. Chromium-nickel zitsulo zosapanga dzimbiri zili ndi mtundu wa titaniyamu-calcium ndi mtundu wochepa wa haidrojeni.Calcium titanate mtundu angagwiritsidwe ntchito AC ndi DC, koma malowedwe osaya AC kuwotcherera, pamene zosavuta kufiira, kuti ntchito magetsi DC.Diameter

7. Elekitirodi iyenera kukhala yowuma, mtundu wa titaniyamu-kashiamu uyenera kuuma pa 150 ° C kwa ola limodzi, ndipo mtundu wochepa wa haidrojeni uyenera kuuma pa 200 ° C mpaka 250 ° C kwa ola limodzi (palibe kuyanika mobwerezabwereza, mwinamwake. ❖ kuyanika ndikosavuta kung'ambika ndikuchotsa) , pewani mafuta omata ndi ma electrode ndi dothi lina, kuti musaonjezere kaboni wa weld ndikusokoneza momwe kuwotcherera.

8. Pofuna kupewa dzimbiri pakati pa maso chifukwa cha kutentha, kuwotcherera panopa sayenera kukhala lalikulu kwambiri, zosakwana mpweya zitsulo elekitirodi pafupifupi 20%, ARC sayenera kukhala yaitali, kuzirala mwamsanga pakati pa zigawo, yopapatiza mkanda ndi koyenera. .

| Chitsanzo | GB | AWS | Diameter (mm) | Mtundu wa Coating | Panopa | Ntchito |

| Chithunzi cha CB-A102 | E308-16 | E308-16 | 2.5-5.0 | Mtundu wa Lime-titania | DC | Ntchito kuwotcherera dzimbiri zosagwira 0cR19Ni9 ndi 0Cr19Ni11Ti zitsulo zosapanga dzimbiri zosachepera 300︒C |

Mapangidwe a Chemical a Deposited Metal

| Chemical Composition of Deposited Metal (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

Mechanical Properties of Deposited Metal

| Mechanical Properties of Deposited Metal | |

| Rm (Mpa) | A(%) |

| ≥550 | ≥35 |

Kulongedza

Fakitale Yathu

Chiwonetsero

Certification Wathu